info

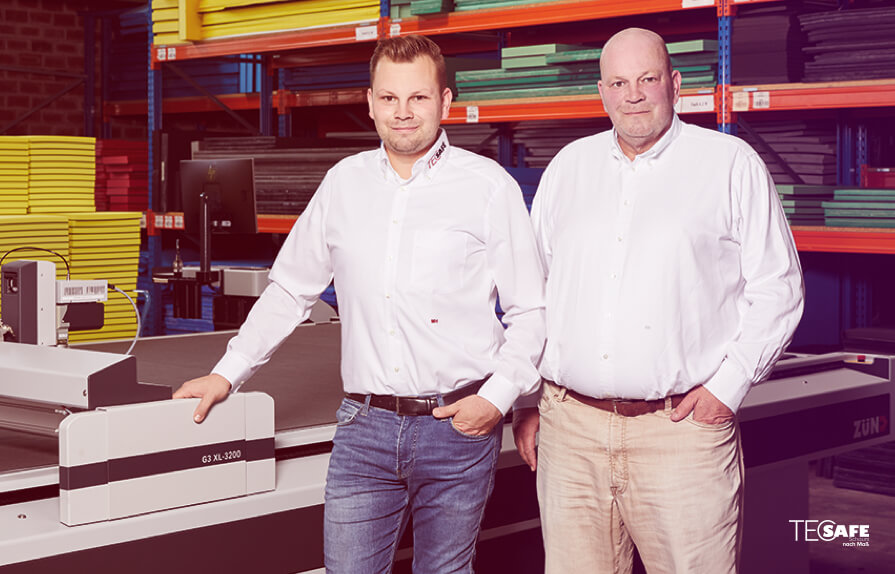

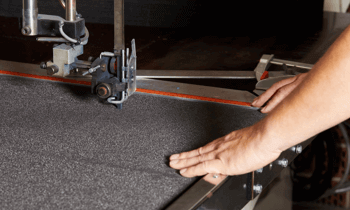

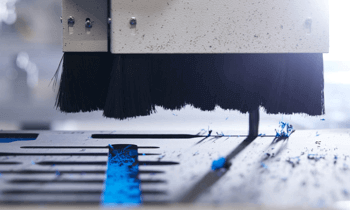

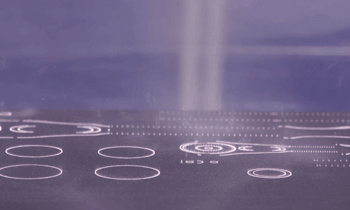

The production process at TECSAFE is already largely digitized, which enables us to process individual inquiries and small quantities just as economically as larger order volumes. This enables us to react very quickly and flexibly to customer requirements and, with delivery times of 2 weeks, we have realized an extremely fast production chain. We are constantly increasing the efficiency of our production chain in order to meet growing customer requirements for just-in-time deliveries and low storage capacities at eye level. As a result, we now have an optimized production chain with our 5 core processes: